Poultry

Custom

Cooling

Solutions

for Poultry

Processing

Reduced bacteria growth &

extended shelf life

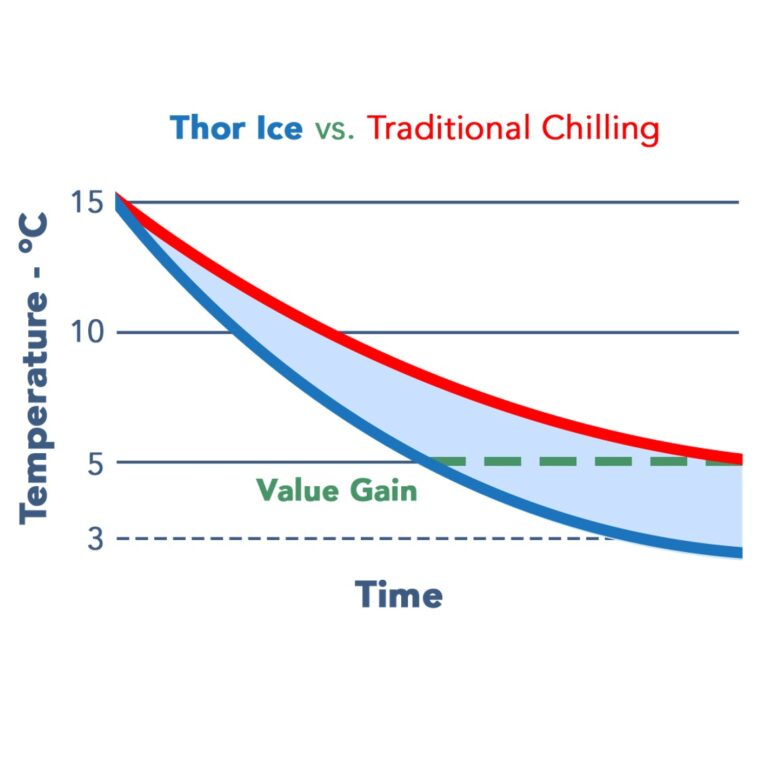

Chilling Solutions for Extended Shelf Life

Our poultry chilling solution involves the patented IceGun® solution, developed specifically for poultry processing. Used to chill colder and more rapidly than existing technologies, the Thor Ice poultry chilling solution helps increase freshness that customers and governmental controls demand, while extending shelf life of poultry. It also increases chilling throughput of the system.

By using controlled slurry ice as a chilling substance and applying Thor Ice poultry chilling solution, processors can successfully improve chilling without making radical and expensive changes to the production processes. Our plug-in and bolt-on solutions save time and money without interrupting production flow.

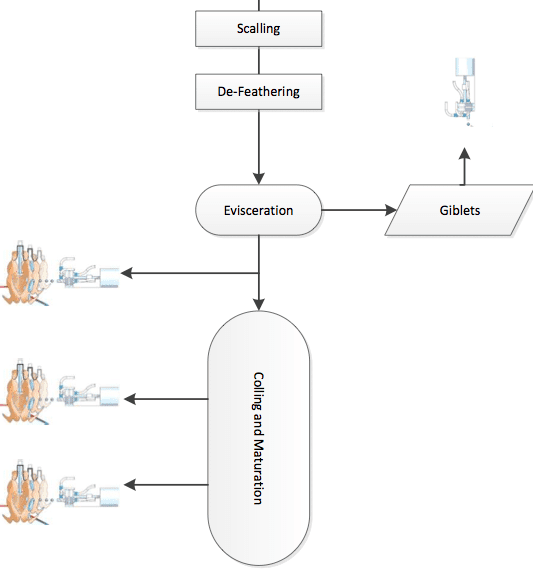

Poultry Processing

Across the industry, increased attention is on bacterial counts, energy costs, and enlarged poultry that is becoming too big for existing lines. Thor Ice has developed retrofit or bolt-on systems that are fully controllable and economical. Their low investment cost saves energy and speeds up production with an optimising effect on operations and environment.

Return on investment is often 1 year or less. Producers are satisfied as they avoid having high investments in and around the chilling chambers, since Thor Ice solutions easily fit into any existing setup by boosting chilling results.

Our systems for poultry processing are intended for all sizes of poultry producers. Thor Ice slurry ice machines and systems for poultry chilling have been developed by and in close collaboration with well established European poultry producers, food institutes, and teams of scientists. We offer solutions that vary in size and can be adjusted to each client’s preferences.

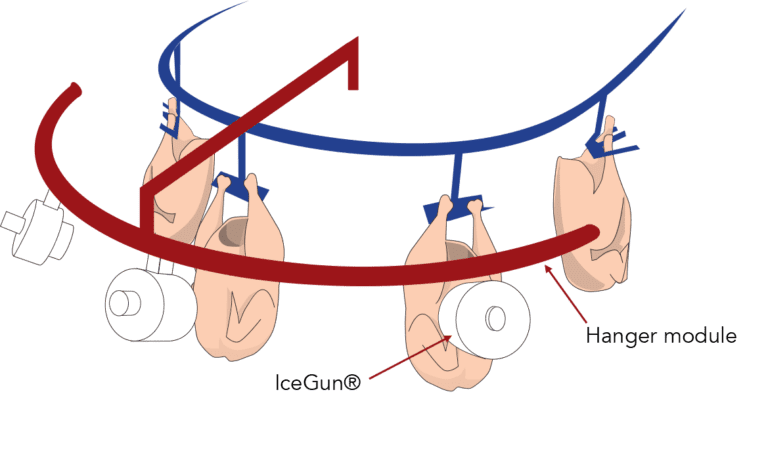

Targeted Chilling

The IceGun® solutions targets specific areas to ensure rapid and effective chilling. Those area include:

- Inside the carcass

- On the breast

- Hard to reach crevasses in the skin

- Behind the neck area

- On and behind drumsticks

Main Benefits of the IceGun® Solution

- Improved yield

- Reduced growth of harmful microbes

- Full monitoring and control from harvesting to consumption

- Optimised operational costs

- Extended shelf life

The system is modular and is designed to complement spray chilling for more efficient chilling of poultry. It uses special spray nozzles, IceGuns®, to apply ice slurry inside and/or outside the poultry as it passes through the chilling lines. The IceGuns® are designed to spray ice slurry at the correct concentration and temperature to maximise cooling efficiency. The number of IceGuns® and their position will differ at each site in order to adapt to the individual processes and to maximise the desired result.

Abilities Our Solution Offers

- Access an innovative hardware and software toolbox: slurry ice machines, storing and distribution units, IceGuns®, data warehouse and reporting tools.

- Rapidly reach lower temperatures and maintain them all the way to the consumption.

- Deliver rapid chilling and lower temperature that will reduce bacteria growth and extend shelf life of products.

- Increase production capacity without making costly modifications to the existing chilling chamber and processing line, as the system works as a plug-in into existing systems.

- Keep the moisture inside the bird by chilling rapidly.

- Chilling from the inside will increase the total area of the bird to be chilled.

- Adjust targeted chilling by aiming the IceGuns at the chosen target areas.

- Chill before the blast/spiral freezer and ensure faster freezing time and reduce costs.

- Reach lower temperature before packaging and storing of products.

- Maintain and improve results with the proactive data monitoring, documentation of the temperature during processing, with online monitoring and a data warehouse.